Looking for our shop site? it's here We are working to amalgamate our websites in 2026. When not flying, Andy has a lot of work to do.

Pilot, will travel, but where do I store my travel items?

These days pilots fly from base to base or operator to operator. They have their travel bag with them safely tucked in the baggage compartment. BUT that is also typically the home of your GPS system. Keeping your travel bag in the baggage compartment while spraying greatly disturbs the air flow around the GPS. This can cause an overheat situation. When working your GPS, try to have your baggage compartment as empty as possible.

Overhauling your spray pump

Here is a 13-minute video on a typical spray pump overhaul for your viewing pleasure! We carry the kits in stock, let us know how we can help.

So your Spray Valve needs overhaul too

We've developed this short video on how to overhaul your spray valve.

Have a view and call us with your questions. Yes we carry all the overhaul kits and parts you may need.

This is not a bad pump seal

If you had product here and on the belly of your aircraft, that would be a bad pump seal. You will see this when your pump is cavitating more aggressively, usually due to fan blades set too flat. Change your blade angle to fix this! By the way, your flow control system will also be grateful.

Avoid Spray System Corrosion

Corrosion eats your booms, causes early wear on spray and loading valves, plugs nozzles and can cause suck back problems.

Here is some preventative maintenance ideas for the end of the spray season.

Thrush Owners, Get that hopper cleaned out!

Transland makes this sump scavenger to help you get those extra gallons out of your hopper for when you need to change products. With this scavenger installed your remaining product in the hopper becomes much less - down to 2-3 gallons!

Fits with Dromaders as well.

Securing your aircraft

These control locks can save your plane when forced to leave on a strip and not in the hangar

Swelling diaphragms? Yuck

Fungicides can be hard on these best friends of yours. Check them often. Do you have spares on hand? They come in both fharapene and viton.

Fungicides can be hard on these best friends of yours. Check them often. Do you have spares on hand? They come in both fharapene and viton.

Don't lose an End Cap

If your end cap blows off at least keep it with the plane by wire locking it to the assembly. Doesn't prevent the misfortune but it does allow you to get back in the air a whole lot sooner. The ulitmate would be to have another screen on hand as well.

If your end cap blows off at least keep it with the plane by wire locking it to the assembly. Doesn't prevent the misfortune but it does allow you to get back in the air a whole lot sooner. The ulitmate would be to have another screen on hand as well.

Chafed Cabling

Sometimes you have to crawl under the plane! We have seen a couple of flow control problems result from chafed cables. Your AME would have made some holes in the aircraft belly to string the flow meter and valve cabling. A grommet is installed to protect the cables. But when that grommet flys off the plane your cables become vulnerable to chafing against the fuselage causing a short.

Sometimes you have to crawl under the plane! We have seen a couple of flow control problems result from chafed cables. Your AME would have made some holes in the aircraft belly to string the flow meter and valve cabling. A grommet is installed to protect the cables. But when that grommet flys off the plane your cables become vulnerable to chafing against the fuselage causing a short.

Electric Fan Brake

The Electric Fan brake has very positive on/off braking.

The Electric Fan brake has very positive on/off braking.

Regularly grab the fan & rotate it back n’ forth. If you feel any looseness or hear clicking, you must have this repaired within hours.

We posted this in the spring (see below), so important now.

Spare Fan Blades

We carry 5 different styles of fan blades in stock. Give us a call today to see if we have what you need.

**Need replacements? This visual may help you, help us, know what ones to order!**

For all Pilots flying on those hotter days!

Even when high heat meets high humidity you must still fly! Remember the effects high temperatures and high density altitude have on aircraft performance. Lift decreases, prop efficiency is lowered and the engine makes less power. Flying conditions can deteriorate so rapidly that after lunch the aircraft may not fly with the same load that was carried earlier in the day. Keep an eye on weather, load lighter and be safe. (This message a re-print of the NAAA PAASS weekly safety alert)

Even when high heat meets high humidity you must still fly! Remember the effects high temperatures and high density altitude have on aircraft performance. Lift decreases, prop efficiency is lowered and the engine makes less power. Flying conditions can deteriorate so rapidly that after lunch the aircraft may not fly with the same load that was carried earlier in the day. Keep an eye on weather, load lighter and be safe. (This message a re-print of the NAAA PAASS weekly safety alert)

For our Radial Pilots

Notice how your Chip Plug bulb has a push to test message on it? Don't be fooled. Pushing this just makes sure your bulb is good. It does NOT test the circuit. Properly test your plug by shorting the center pin to ground with your master switch on - if the light comes on you know your chip plug is working.

Notice how your Chip Plug bulb has a push to test message on it? Don't be fooled. Pushing this just makes sure your bulb is good. It does NOT test the circuit. Properly test your plug by shorting the center pin to ground with your master switch on - if the light comes on you know your chip plug is working.

And don't keep flying if the light comes on, land and check it out. Sometimes it is a false alarm but most times it is an early warning indicator that you have an issue. Save your engine and minimize repair costs.

Know thy engine! When the wind is blowing and you have caught up on your sleep, grab your flashlight and get intimate with your radial engine. "Working engines are always talking to you" says our Director of Maintenance Allan, "if you are listening and observing closely you will detect potential issues and can monitor them or get some advice before a bigger issue develops." He also reminds pilots to check over their engine before any pressure washing. "Again, a dirty engine and dirty airframe will highlight troubles."

Know thy engine! When the wind is blowing and you have caught up on your sleep, grab your flashlight and get intimate with your radial engine. "Working engines are always talking to you" says our Director of Maintenance Allan, "if you are listening and observing closely you will detect potential issues and can monitor them or get some advice before a bigger issue develops." He also reminds pilots to check over their engine before any pressure washing. "Again, a dirty engine and dirty airframe will highlight troubles."

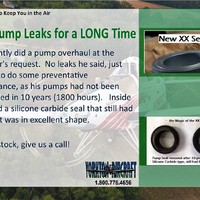

Stop Pump Leaks for a LONG time

We have been recommending the use of the Silicone Carbide seals

We recently did a pump overhaul at the customer's request, since it had been a long time in his view. No leaks he said, just wanted to do some preventative maintenance. Inside we found a silicon carbide seal (see the picture below) that still had life left, it was in excellent shape. After some research we determined the last pump overhaul to be about 10 years ago which tallied to about 1,800 hours in service.

Here is a picture of the removed seal.

These seals are more costly than the standard seal but leaks and overhauls can be more costly.

These seals are more costly than the standard seal but leaks and overhauls can be more costly.

Call Allan to discuss this further if you like.

Seals are in stock for both Transland and Agrinautic pumps.

Lane Brake Flyers

Before you start the season, we recommend pilots/operators check for free play between the Lane brake hub and the shaft of their pump. The ideal is NO free play - a small detectable amount may keep you going. However, significant free play means you should change / replace your key way before it breaks and puts you down.

This is particularly recommended for those who use the Lane brake to stop their pump (versus the conventional manual valve open/close function).

Non-Certificated operators (Flying Farmer)

In February 2016 Transport Canada released this Advisory Circular (AC 600-007) to provide information and guidance to industry, describing the acceptable means for Flying Farmers to demonstrate compliance with the regulations and standards.

Combatting fatigue in ag aviation

After 15 hours of continuous wakefulness, many people function at approximately the same level as those who are legally drunk!

These facts and more importantly, some great tips on managing fatigue can be found in this quick read thanks to our friends at the Natonal Agricultural Aviation Association.

Here is a great video on the use of pesticides in Organics

Are pesticides used in organic farming different from those used in conventional farming?

Important point: we couldn't feed the world if we didn't use some form of pesticide. And one could also add that food prices would be sky high and only the rich could afford to eat under pesticide free production models.

Keep your windshield clean

Here's a quick read on the do's and don'ts of windshield cleaning.

Here is a checklist we use to teach new people on proper window care.

Changing tires?

Change the tube too! Don't try to save dollars here. It will cost you in time down the road. What more is there to say.

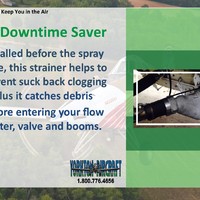

Catch debris before it puts you down

Check out this Inline Strainer. HUGE downtime and annoyance saver!

Manage your pressure - your pump & boom pressure that is

This is an innovation of Yorkton Aircraft Service. We carry the kit parts on hand.

CP Nozzle maintenance

Here is a handy guide for working with your CP equipment.

Suckback and correct plumbing

We've put this 3 pager together as so many people have questions. But please still call us with your questions.

Dr, Dennis Gardisser's Rules of Thumbs

Over the years, Yorkton Aircraft has attended many of Dr. Gardisser's spray pattern presentations. We noticed he uses a number of "rules of thumb" as reference and quick memory facts for proper spray application. We developed this paper with permission from Dr. Gardisser. Take a moment to read it, download it even. You will find it informative.

Components of a sound maintenance program

Obviously an aircraft that is well maintained will do its part in ensuring the pilot is safe.

But the consequences of a pilot having to deal with a poorly maintained aircraft and/or a weak maintenance program can be costly to the operation as well.

How?

Proper Training

Knowing how to fly the aircraft is not enough.

Make sure the pilot completely understands how the aircraft operates including all of its systems - do they know what to look for, listen for, and feel for to ensure everything is operating properly and to detect problems. "Airplanes talk to the pilot and the maintenance crew all the time" says our Director of Maintenance Allan, "you just need to learn their language!"

Include maintenance training as part of the annual re-currency training and competency checks.

Adopt Only Excellent Maintenance Practices

Maintaining your aircraft by only the minimum required standards will give you only minimum efficiency and low return.

Maximize efficiency and return on your investment by maximizing the longevity of your engine and accessories - longevity can only be realized with excellent maintenance practices.

Make certain everyone knows the maintenance standards and schedules and maintains proper records to ensure schedules are met.

Develop Strong Liaisons - Plan for the Unplanned

Particularly with your AMO and its AMEs - develop a strong winter maintenance program and arrange dependable in-season support.

Give your pilots authority to contact the AMO with their questions and observations so they can make the correct operating decisions.

Do you have key parts on the shelf or know where you can get parts to minimize downtime.

A sound maintenance program will pay you back in:

- Safety

- Dependability

- Performance

- Peace of Mind

- Value

.jpg)